To hone a cylinder with sandpaper, start with coarse grit and gradually move to finer grit for a smooth finish. Ensure to use long, even strokes for uniformity in the cylinder surface.

Honing a cylinder with sandpaper is a crucial step in improving engine performance and efficiency. By following the proper technique, you can achieve the desired cylinder surface that will enhance engine functionality. Whether you are working on a small engine or a larger one, honing with sandpaper requires patience and precision.

In this guide, we will explore the steps involved in honing a cylinder with sandpaper, providing you with the knowledge and skills to tackle this task effectively.

Understanding Cylinder Honing

Honing a cylinder is an essential step in the process of engine rebuilding or repair. It involves removing small amounts of material from the inner walls of the cylinder using abrasive tools like sandpaper or flex hones. Cylinder honing helps achieve a smooth and uniform surface, ensuring proper oil retention, piston ring seating, and overall engine performance. In this section, we will delve deeper into what cylinder honing is and why it is crucial in engine maintenance.

What Is Cylinder Honing?

Cylinder honing is a machining process that enhances the condition of the cylinders by removing imperfections and creating a precise, uniform bore. It involves using abrasive tools, typically sandpaper or specialized honing stones, to remove metal material from the cylinder walls. This process generates crosshatch patterns or grooves on the cylinder surface, which promote oil retention and effective lubrication. The primary goal of cylinder honing is to achieve proper ring-to-wall contact, ensuring optimal sealing and minimizing oil consumption.

Importance Of Cylinder Honing

Cylinder honing plays a crucial role in engine performance and longevity. Here are some reasons why honing is vital:

- Optimal Ring Sealing: Honing creates a roughened surface with microscopic grooves that assist in holding oil and promoting proper ring seating. This leads to improved compression and prevents oil from entering the combustion chamber.

- Reduced Friction: The crosshatch pattern created during honing helps retain lubrication, reducing friction between the rings and the cylinder wall. This minimizes wear and tear, enhancing the lifespan of both the rings and the cylinder.

- Improved Heat Transfer: Honing removes irregularities, allowing for better heat dissipation from the piston to the cylinder walls. This helps maintain optimal operating temperatures and prevents overheating, which can result in engine damage.

- Enhanced Oil Retention: The grooves created by honing hold oil, preventing excess oil consumption and ensuring adequate lubrication throughout the engine’s operation. This leads to smoother performance and prolonged engine life.

- Correct Bore Geometry: Cylinder honing ensures the cylinder bore maintains its proper roundness, straightness, and size. This precision is crucial for maintaining proper compression ratios, preventing blow-by, and maximizing power output.

Understanding cylinder honing is essential for anyone involved in engine maintenance. By honing the cylinder walls correctly, you can ensure improved engine performance, increased durability, and reduced oil consumption. In the next section, we will discuss how to hone a cylinder using sandpaper.

Selecting The Right Sandpaper

To hone a cylinder with sandpaper effectively, the first crucial step is Selecting the Right Sandpaper. This process starts with understanding the

Grit Types And Sizes

as well as

Determining The Initial Grit

for the task at hand.

Grit Types And Sizes

When it comes to sandpaper, the grit size indicates coarseness or fineness. Common types include silicon carbide for metal and aluminum oxide for wood. Grit sizes range from

- Coarse (40-60)

- Medium (80-120)

- Fine (150-180)

- Very Fine (220-240)

Choose based on the cylinder material and the level of smoothing required.

Determining The Initial Grit

For a rough cylinder, start with a coarse grit to remove imperfections. For a smoother finish, progress to finer grits gradually. The initial grit choice sets the foundation for the honing process. It is essential to match the grit to the condition of the cylinder surface.

Preparing The Cylinder

Preparing the cylinder is a crucial step in the process of honing it to perfection. Before you dive into honing, you must make sure that the cylinder is clean and free from any damage. This involves thorough cleaning, meticulous inspection, and necessary repairs to ensure that the cylinder is in optimal condition for honing.

Cleaning The Cylinder

Effective cleaning is fundamental to the cylinder honing process. Start by removing any dirt, debris, or old gasket material from the cylinder using a suitable solvent and a rag. Ensure that the inner surface is completely clean to avoid any interference with the honing process.

Inspecting For Damage

Thoroughly inspect the cylinder for any signs of damage such as scratches, pitting, or wear. Using a flashlight, carefully examine the entire surface to detect any imperfections. If any damage is detected, assess the severity and determine whether it can be rectified through honing or if further repairs are necessary.

Sandpaper Hone Step-by-step

Honing a cylinder with sandpaper is a precise process that requires attention to detail and the right techniques. In this guide, we will walk you through the step-by-step process of honing a cylinder using sandpaper. Following these steps will help you achieve a smooth and polished finish on your cylinder, ensuring optimal performance.

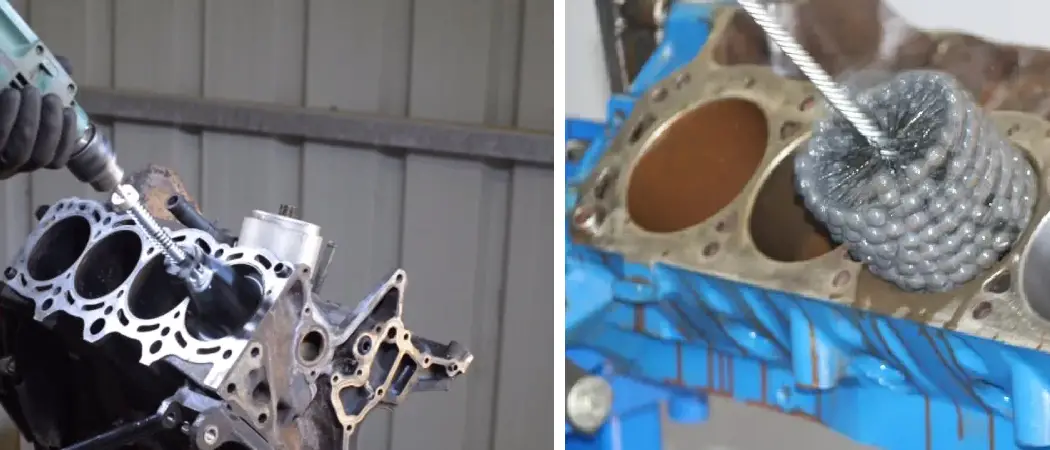

Securing The Cylinder

Before you start honing the cylinder, it is crucial to secure it properly to avoid any accidents. Here’s how to do it:

- Ensure that the cylinder is cleaned thoroughly to remove any dirt or debris.

- Use a cylinder vise or cylinder holding fixture to secure the cylinder firmly in place during the honing process.

Securing the cylinder ensures stability and prevents any unwanted movements that could impact the quality of the hone.

Applying Lubrication

Lubrication is essential to reduce friction and heat during the honing process. Follow these steps to apply lubrication:

- Choose a suitable honing oil or lubricant specifically designed for engine cylinders.

- Apply a thin layer of lubricant evenly to the surface of the cylinder and the sandpaper.

- Ensure that the lubricant is evenly distributed and there are no dry spots.

Proper lubrication will help the sandpaper glide smoothly over the cylinder, preventing overheating and ensuring consistent results.

Starting With The Initial Grit

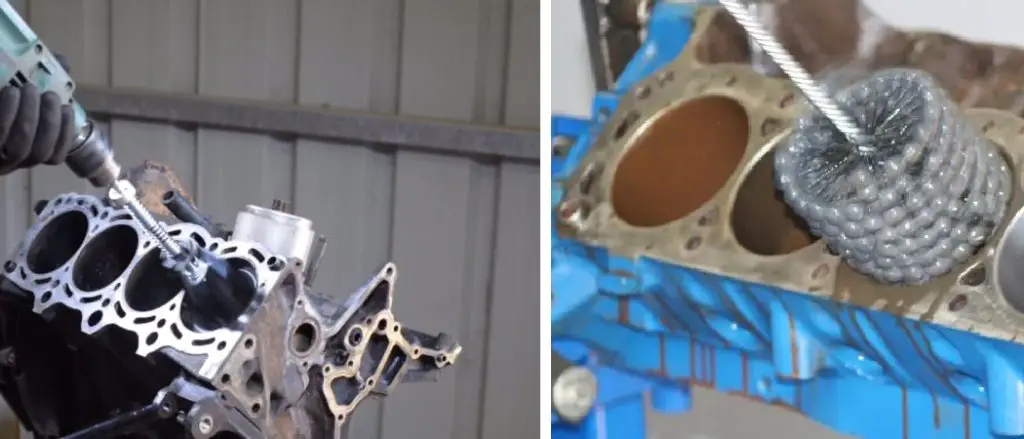

The first step in the honing process is to start with the initial grit sandpaper. Here’s what you need to do:

- Choose the appropriate grit sandpaper depending on the condition of your cylinder. Coarser grits are suitable for cylinders with more imperfections.

- Attach the sandpaper securely onto the honing tool, ensuring it is centered properly.

- Begin honing the cylinder by moving the honing tool up and down in a smooth, controlled motion.

Starting with the initial grit allows you to remove any roughness on the cylinder’s surface, preparing it for further honing.

Working Through The Grits

After completing the initial honing, it’s time to work through the grits to achieve a finer finish. Here’s what you should do:

- Progressively move to higher grit sandpapers, gradually refining the cylinder’s surface.

- Repeat the honing process with each subsequent grit, ensuring even and consistent strokes.

- Inspect the cylinder periodically to gauge the progress and check for any remaining imperfections.

Working through the grits gradually smooths the cylinder’s surface, resulting in a polished finish that improves performance.

Measuring And Testing

To hone a cylinder with sandpaper, start by thoroughly cleaning the cylinder. Next, wrap the sandpaper around a cylinder hone and lubricate it with oil. Rotate the hone back and forth in the cylinder until the desired surface finish is achieved.

Checking Cylinder Bore Size

Determine the cylinder bore size using a dial bore gauge for accuracy.

Compare the bore size to specifications to ensure it meets requirements.

Performing A Leak Down Test

Conduct a leak down test to assess cylinder condition and seal integrity.

Identify any leaks by monitoring air pressure and listening for escaping air.

Finishing Touches

After honing the cylinder with sandpaper, it’s important to focus on the finishing touches to ensure a smooth and polished surface. This will not only enhance the performance of the cylinder but will also extend its lifespan. In this section, we will discuss two crucial steps for achieving that perfect finish: removing any residual material and deburring the cylinder.

Removing Any Residual Material

Before moving forward with the finishing touches, it’s essential to remove any remaining material left behind from the honing process. Residual material can affect the cylinder’s performance and compromise its durability. To eliminate this, follow these steps:

- Clean the Cylinder: Start by cleaning the cylinder thoroughly. Use a non-abrasive cleaner and a soft brush to remove any loose particles or debris. Make sure to reach all the crevices and corners of the cylinder.

- Inspect for Residual Material: Once the cylinder is clean, carefully inspect its surface for any remaining material. Pay close attention to the cylinder walls and look for any rough spots or imperfections.

- Sandpaper: If you notice any residual material, gently sand the affected areas with a fine-grit sandpaper. Use smooth, circular motions and apply a light pressure. Be sure not to overdo it, as excessive sanding can lead to damage.

- Clean Again: After sanding, clean the cylinder once more to remove any dust or debris resulting from the sanding process. You can use compressed air or a soft cloth to ensure the cylinder is free from any particles.

Deburring The Cylinder

Deburring the cylinder is another crucial step in the finishing process. Deburring involves removing the sharp edges and burrs that can form on the cylinder during honing. These sharp edges can impact the cylinder’s performance and cause premature wear. Here’s how to deburr the cylinder effectively:

- Identify the Burrs: Carefully inspect the cylinder’s surface to locate any sharp edges or burrs. These can often be found at the entrance and exit points of the cylinder.

- Use a Deburring Tool: Once you’ve identified the burrs, use a specialized deburring tool to remove them. The tool should be applied gently in a back-and-forth motion, gradually removing the sharp edges.

- Check for Smoothness: After deburring, run your finger along the cylinder’s surface to ensure it feels smooth and free from any rough patches. If you encounter any remaining burrs, repeat the deburring process until the cylinder is completely deburred.

With these finishing touches, your cylinder should now have a smooth and polished surface, ready to deliver optimal performance. Remember, proper maintenance and occasional honing will help keep your cylinder in excellent condition for a long time.

Frequently Asked Questions For How To Hone A Cylinder With Sandpaper

What Grit Should I Use To Hone Cylinders?

Use a 220 grit to hone cylinders for initial roughing. Then, switch to a 400 grit for smoothing and finishing. This process ensures a balanced surface for the cylinders.

What Grit Sandpaper For Cylinder Bore?

Use 220 grit sandpaper for cylinder bore to achieve optimal results in smoothing and finishing the surface.

What Is The Best Lubricant To Use When Honing A Cylinder?

The best lubricant for honing a cylinder is a specialized honing oil. It provides smooth motion, reduces friction, and ensures accurate results. Using the right lubricant is crucial for a successful honing process and maintaining the cylinder’s integrity.

Do You Hone Cylinders Dry Or Wet?

Cylinders are honed with a wet process, using lubricants or coolants. This improves surface finish, removes debris, and prevents overheating.

Conclusion

To sum up, honing a cylinder with sandpaper is a detailed but rewarding process to improve performance. With patience and precision, you can achieve smoother surfaces and enhance engine efficiency. Remember, proper technique and quality sandpaper are key for optimal results in cylinder honing.

Master this skill for better engine performance.