To fix solvent pop, sand the affected area and apply a new coat of paint.

Understanding Solvent Pop

Solvent pop refers to bubbles or blisters that form on a painted surface due to the presence of trapped solvents. It is a common issue in the world of painting and finishes, impacting the overall appearance and durability of a project. Understanding the causes and effects of solvent pop is crucial for effective resolution.

Causes Of Solvent Pop

1. Incorrect paint application techniques.

2. Excessive spraying of thick coats of paint.

3. Inadequate flash-off time between coats.

Effects Of Solvent Pop

1. Diminished aesthetic appeal of the finish.

2. Reduced durability of the paint.

3. Potential damage to the underlying substrate.

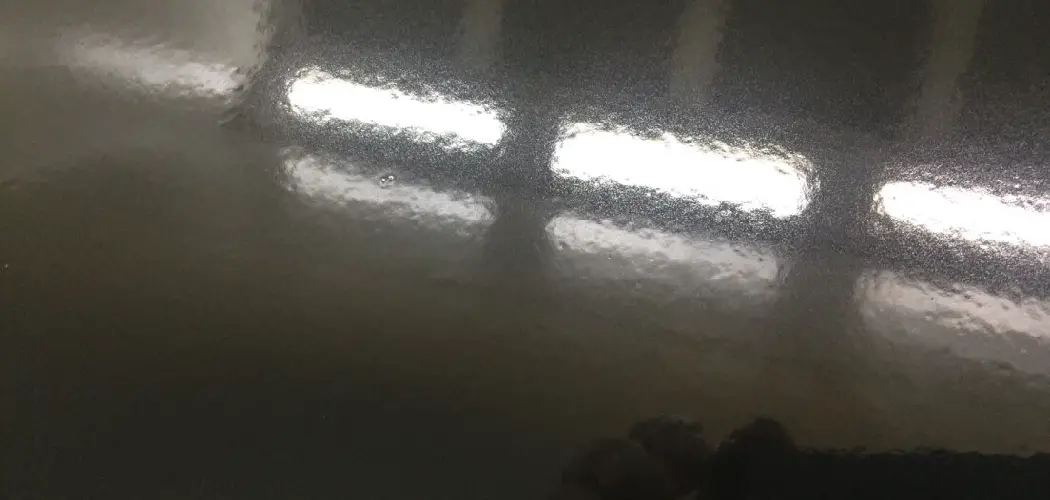

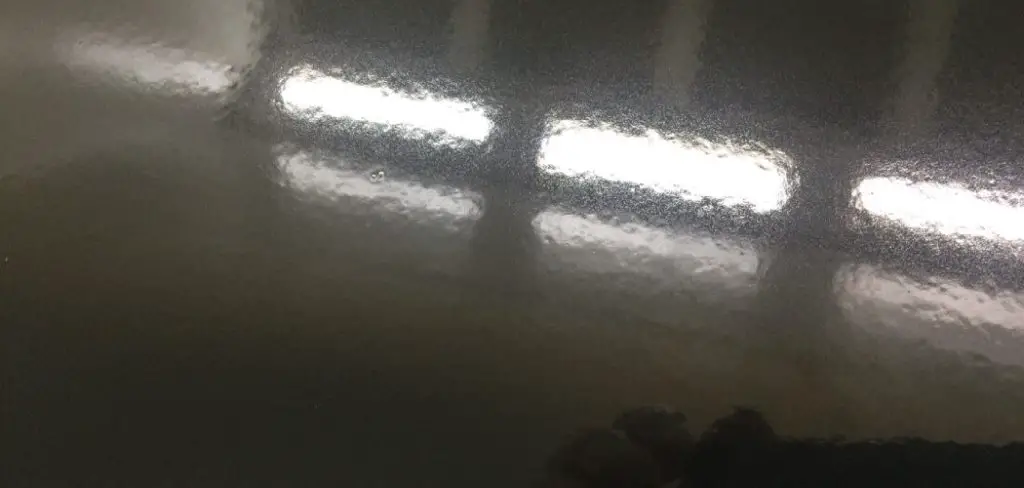

Identifying Solvent Pop

Identifying solvent pop is crucial for effective paint repairs. Learn practical steps on how to fix solvent pop and restore a smooth, flawless finish to your project.

When it comes to achieving a flawless finish on a painted surface, solvent pop can be a frustrating issue. Solvent pop refers to tiny bubbles or defects that appear in the paint film due to trapped solvents evaporating too quickly. If left unaddressed, solvent pop can mar the appearance of your painted surface.

Visual Inspection

Visual inspection is the first step in identifying solvent pop. By closely examining the painted surface, you can look for telltale signs of defect. Here are some visual cues to be on the lookout for:

- Small, crater-like depressions on the surface

- Irregular patterns of tiny bubbles

- Rough or bumpy texture

- Visible paint film separation

If you notice any of these visual signs, it is a good indication that you might be dealing with solvent pop.

Tactile Inspection

Besides visual cues, you can also perform a tactile inspection to confirm the presence of solvent pop. By gently running your fingertips over the painted surface, you may be able to feel the defects caused by trapped solvents. Keep in mind that solvent pop can vary in severity, so be diligent in your examination.

If your fingertips detect irregularities, such as roughness, unevenness, or small depressions, it is likely that solvent pop is present.

Preventive Measures

When mixing paint, ensure the components are well blended and the correct proportions are maintained. Inadequate mixing can lead to solvent pop issues, so pay close attention to the manufacturer’s guidelines for the specific paint being used.

When applying paint, use consistent and even spraying techniques to achieve a smooth and uniform finish. Avoid overspraying or holding the sprayer too close to the surface, as this can result in solvent pop. Aim for a steady, controlled application to minimize the risk of solvent pop.

Fixing Solvent Pop

Solvent pop occurs when bubbles or craters form on a surface due to solvent evaporation during the curing process. This issue can affect the finish and appearance of a painted surface. Fortunately, fixing solvent pop is possible through various methods, and it’s essential to address the problem promptly to ensure a smooth and professional finish.

Sanding And Repainting

One effective way to fix solvent pop is by sanding the affected area to remove the blemishes and then repainting it. Ensure the surface is clean and dry before sanding to prevent further imperfections. Use a fine-grit sandpaper to gently sand the area, followed by a higher-grit sandpaper for a smoother finish. After sanding, clean the surface to remove any dust and debris before applying a fresh coat of paint.

Using Retarders

An alternative method to address solvent pop is by using retarders in the paint mixture. Retarders slow down the drying process, allowing solvents more time to evaporate evenly, preventing the formation of bubbles or craters. When using retarders, follow the manufacturer’s instructions and consider the environmental conditions to ensure the best results.

Expert Tips For Solvent Pop Repair

Solvent pop is a common issue in the painting process that can affect the overall finish and appearance of a project. Fortunately, there are expert techniques that can help address and prevent solvent pop, ensuring a high-quality and professional finish. By applying the correct pressure, maintaining control over temperature and humidity, and implementing thorough repair strategies, you can effectively tackle solvent pop issues. Let’s delve into some expert tips for solvent pop repair.

Applying Correct Pressure

When spraying, maintain consistent pressure from the gun to ensure an even distribution of the coating. This helps minimize the formation of solvent pop. Additionally, implementing proper spray gun technique and adjusting the pressure based on the viscosity of the coating can contribute to a smoother finish.

Temperature And Humidity Control

Controlling the temperature and humidity in the painting environment is crucial for minimizing solvent pop. Ensure that the temperature and humidity levels are within the recommended range for the specific coating being used. Sudden temperature changes and high humidity can lead to solvent pop, so monitoring and adjusting these factors is vital for prevention.

Advanced Solutions

Utilizing Heat Lamps

- Heat lamps can quickly and effectively eliminate solvent pops on surfaces.

- Make sure to keep the lamp at a safe distance to prevent damage.

- The heat gently evaporates the trapped solvent beneath the surface.

Polishing Techniques

- Polishing can help smooth out imperfections caused by solvent pops.

- Use a fine polishing compound to achieve a glossy finish.

- Gently buff the surface in a circular motion for best results.

Reviewing Common Mistakes

Start Blog Content

Many painters encounter solvent pop issues due to some common mistakes. Understanding these mistakes can help prevent future problems.

Rushing The Drying Process

Rapidly drying paint can lead to solvent pop issues. It is essential to allow sufficient drying time between coats to prevent this problem.

Ignoring Manufacturer Guidelines

Not following the manufacturer’s instructions can result in solvent pop. Always adhere to the recommended mixing ratios, application techniques, and drying times to achieve the best results.

End Blog Content

Final Thoughts

Solvent pop is a common issue that many automotive painters face. However, with persistence and practice, it can be fixed effectively. Consulting professionals can also provide valuable insights and guidance in resolving solvent pop problems.

Persistence And Practice

To fix solvent pop, persistence is key. It may take several attempts and adjustments to achieve the desired results. Don’t get discouraged if the first few tries don’t yield the perfect outcome. Keep experimenting, making small changes, and learning from each attempt.

Practice makes perfect, and the same applies to fixing solvent pop. The more you practice, the better you become at identifying the causes and applying the appropriate solutions. Take the time to familiarize yourself with the techniques and processes involved in preventing and repairing solvent pop.

Consulting Professionals

When persistent efforts and practice aren’t producing the desired results, it’s wise to consult professionals. Experienced painters and automotive experts can provide valuable insights and tips to address solvent pop issues effectively. They have the knowledge and expertise to diagnose the root causes of solvent pop and suggest appropriate solutions.

A professional’s guidance is invaluable when it comes to fixing solvent pop. They can help you navigate through the different variables that may be contributing to the problem, such as paint viscosity, curing temperatures, or spray gun adjustment. With their guidance, you can make the necessary adjustments and avoid common pitfalls.

Consulting professionals can save you time and resources by providing efficient solutions to your solvent pop issues. Their expertise enables them to quickly identify the problem and offer targeted remedies. With their guidance, you can avoid wasting time and costly materials while improving your painting results.

Remember, solving solvent pop issues requires both persistence and practice. Additionally, seeking the advice of professionals can provide valuable insights and save you time and resources. Stay patient, keep learning, and soon you’ll fix solvent pop like a pro.

Frequently Asked Questions On How To Fix Solvent Pop

How Do You Repair Solvent Pop?

To repair solvent pop, sand affected area, fill with body filler, and repaint for a smooth finish.

Why Am I Getting Solvent Pop?

Solvent pop occurs due to trapped solvents escaping during drying, leaving bubbles on the surface.

Can You Sand And Buff Solvent Pop?

Yes, you can sand and buff solvent pop to remove it from the surface. It is important to carefully follow the recommended procedure to achieve the desired results.

How Do You Fix Solvent Pop In Single Stage Paint?

To fix solvent pop in single stage paint, sand down the affected area, then apply a fresh coat of paint. Properly adjust the spray gun and ensure the correct thinning of paint for a smooth finish. Use appropriate drying techniques and conditions to prevent future solvent pop.

Conclusion

To conclude, fixing solvent pop is a crucial step in achieving a flawless finish for your projects. By following the tips and techniques mentioned in this blog post, you can effectively address and prevent solvent pop issues. Remember to properly prepare the surface, use high-quality materials, maintain proper spraying techniques, and allow sufficient drying time.

By implementing these steps, you can ensure a professional and visually appealing outcome for your work.