To fix alternator bearing noise, you need to replace the worn-out bearings.

Diagnosing Alternator Bearing Noise

When diagnosing alternator bearing noise, it’s crucial to pinpoint the source accurately. Identifying the Source of the Noise will lead you to the root cause efficiently. Let’s break down the process into manageable steps.

Identifying The Source Of The Noise

Begin by pinpointing where the noise is coming from. Listen closely to determine if it’s emanating from the alternator area.

Tools Needed For Diagnosis

- Stethoscope for precise noise detection

- Socket wrench set for component accessibility

- Safety goggles to protect your eyes during inspection

Preparing For Repair

If you’ve been noticing an annoying squealing or grinding noise coming from your vehicle’s engine bay, it could be a sign of a worn-out alternator bearing. Ignoring this issue can lead to more serious problems down the road, so it’s crucial to address it promptly. While fixing an alternator bearing noise might seem daunting, with the right preparation and safety measures, you can resolve it yourself without breaking a sweat. In this article, we’ll guide you through the necessary steps to fix the alternator bearing noise in your vehicle.

Gathering Necessary Materials

Before you get started, it’s essential to have all the required tools and materials within reach. This ensures a smooth and uninterrupted repair process. Here’s a list of items you’ll need:

- Socket set with various sizes

- Ratchet wrench

- New alternator bearing

- Bearing puller tool

- Flat-head screwdriver

- Clean cloth or rag

- Safety goggles

Ensuring Safety Measures

Working on your vehicle’s alternator involves handling potentially hazardous components, so taking proper safety precautions is crucial. Here’s what you need to do:

- Disconnect the negative terminal of the battery to prevent any electrical accidents.

- Wear safety goggles to protect your eyes from potential debris or substances that may dislodge during the repair process.

- Allow the engine to cool down for at least 30 minutes before beginning the repair to avoid any burns.

Steps To Fix Alternator Bearing Noise

When your car’s alternator starts making a loud, whining noise, it can be a sign of a faulty alternator bearing. Ignoring this issue can lead to further damage to the alternator and other components. Fortunately, fixing alternator bearing noise is a relatively straightforward process that can be done with the right tools and a bit of mechanical know-how. Here are the steps to fix alternator bearing noise.

Step 1: Disconnecting The Battery

Begin by disconnecting the battery to prevent any electrical shock or damage during the repair process. Locate the car’s battery and use a wrench to remove the negative (-) terminal from the battery.

Step 2: Removing The Alternator

Next, locate the alternator in your car’s engine bay. Refer to your car’s manual for the exact location if needed. Use a wrench to loosen the alternator belt tension and remove the belts from the alternator pulley. Once the belts are removed, use a socket wrench to loosen and remove the bolts securing the alternator in place. Carefully remove the alternator from the engine bay.

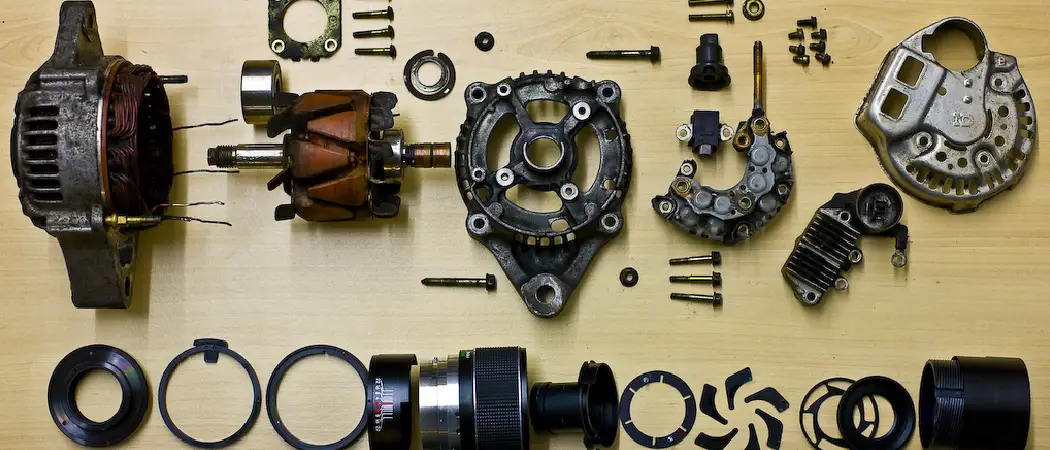

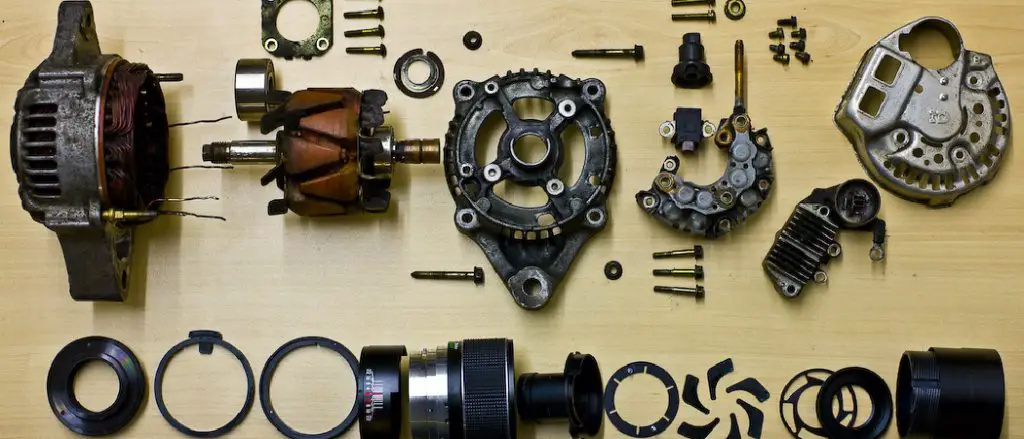

Step 3: Replacing The Bearing

With the alternator removed, locate the alternator bearing that is causing the noise. Using the appropriate tools, carefully remove the old bearing from the alternator and replace it with a new one. Ensure that the new bearing is installed securely and in the correct orientation.

Step 4: Reinstalling The Alternator

Once the new bearing is in place, carefully reinstall the alternator back into the engine bay. Ensure that all bolts are tightened securely, and the belts are properly reinstalled and tensioned. Reconnect the negative (-) terminal of the battery and start the car to check for any remaining noise.

“`

Credit: www.quora.com

Tips For Silent Driving Post-repair

If you’ve recently fixed your alternator bearing noise issue, you’re probably eager to enjoy a quiet and smooth driving experience. To ensure your post-repair driving is truly silent, there are some essential tips you should keep in mind. By incorporating these practices, you can maintain the longevity of your alternator and enjoy a noise-free ride for miles to come.

Regular Maintenance Practices

Regular maintenance is crucial in preventing any future alternator bearing noise or other issues. By implementing the following practices, you can extend the lifespan of your alternator:

- Keep the alternator clean: Regularly remove any dirt or debris that has accumulated around the alternator to prevent damage to the bearings.

- Inspect the drive belt: Check for any signs of wear or damage on the drive belt and replace it if necessary. A worn-out belt can lead to increased noise and strain on the alternator bearings.

- Monitor battery health: Weak or faulty batteries can put additional strain on the alternator. Keep a close eye on your battery’s condition and replace it if needed.

- Ensure proper belt tension: The drive belt should have the correct tension to prevent slipping and unnecessary stress on the alternator bearings.

Listening For Warning Signs

To avoid potential alternator bearing noise issues before they escalate, it’s important to listen for warning signs. Keep your ears open for the following sounds:

- Clunking noise: If you hear a clunking sound coming from the engine, it may indicate that the alternator bearings are worn out and need immediate attention.

- Grinding noise: A grinding noise can be a sign of severe damage to the alternator bearings. If you hear this noise, it’s crucial to have your alternator inspected and repaired as soon as possible.

- Squealing noise: A high-pitched squealing noise when you start your car can indicate a loose or misaligned belt. Addressing this issue promptly will help prevent any further damage to the alternator bearings.

By promptly addressing any warning signs you hear, you can prevent small issues from turning into significant and costly problems down the road.

Common Mistakes To Avoid

Common Mistakes to Avoid:

Skipping Proper Diagnosis:

Misdiagnosing issues can lead to wasted time and money. Always conduct thorough testing before proceeding.

Using Incorrect Tools:

Using improper tools can damage the alternator. Ensure you have the right tools for the job.

When To Seek Professional Help

Complex Repairs Involved

If the alternator bearing noise persists after basic troubleshooting, consulting a professional mechanic is necessary.

Specialized tools may be needed, including a bearing puller or press, which require expertise.

Dealing with electrical components poses risks, necessitating professional knowledge to avoid accidents.

Lack Of Experience

Attempting repairs without proper knowledge can result in costly mistakes and further damage.

Avoid DIY if unsure of handling intricate auto parts to prevent complications.

Trusting a skilled technician ensures efficient resolution and peace of mind.

Frequently Asked Questions For How To Fix Alternator Bearing Noise

How Do You Fix A Noisy Alternator Bearing?

To fix a noisy alternator bearing, you need to replace the bearing or the entire alternator unit. First, remove the alternator from the vehicle. Then, disassemble it to access the bearing. Replace the bearing with a new one, or install a new alternator, and reassemble everything back.

Can You Lubricate Alternator Bearings?

No, you cannot lubricate alternator bearings. They are sealed and pre-lubricated for their lifespan. Trying to lubricate them can cause damage.

Can You Drive With Bad Alternator Bearing?

Yes, you can drive with a bad alternator bearing, but it is not recommended. A bad bearing can cause the alternator to malfunction, leading to electrical problems and potential breakdowns. It is best to have it replaced as soon as possible to avoid further damage to your vehicle.

What Can I Spray On A Noisy Alternator?

Spray silicone lubricant on a noisy alternator to reduce squeaking sounds and improve performance.

Conclusion

Fixing alternator bearing noise is crucial for maintaining the smooth operation of your vehicle. By following the steps mentioned in this blog post, you can address the issue effectively and prevent further damage. Regular maintenance and prompt repairs are essential to ensuring the longevity of your alternator and avoiding potential breakdowns.

Take action now to restore the quiet running of your alternator and enjoy a hassle-free driving experience.