Choosing The Right Heat Tape

Choosing the right heat tape for your PEX pipe is essential to ensure the safety and efficiency of the installation. With various types of PEX pipes available in the market, understanding the specific requirements of your system is crucial in selecting the appropriate heat tape. Additionally, the climate and environment also play a pivotal role in choosing the right heat tape for your PEX pipe installation.

Evaluating The Pex Pipe Type

Before selecting the heat tape, it is important to evaluate the type of PEX pipe you are using. There are three primary types of PEX pipes: PEX-A, PEX-B, and PEX-C. Each type has different properties and requires specific considerations when choosing heat tape. PEX-A pipes, known for their flexibility, may require a different type of heat tape compared to PEX-B or PEX-C pipes.

Selecting The Appropriate Heat Tape Type

Once you have evaluated the type of PEX pipe being used, the next step is to select the appropriate heat tape type. There are various types of heat tapes, including self-regulating, constant wattage, and mineral insulated. Each type has its own set of advantages and applications. By understanding the specific heating requirements of your PEX pipe, you can choose the most suitable heat tape to ensure effective and safe operation.

Gathering Required Tools And Materials

Gathering Required Tools and Materials

Identifying Necessary Tools

Identifying Necessary Tools

Pex pipe cutter: essential for cutting Pex pipe accurately.

Assembling Materials for Installation

Assembling Materials For Installation

Heat tape: to protect Pex pipes from freezing.

Insulation: insulates the pipe from external cold.

Thermostat: regulates heat tape temperature.

Preparing The Pex Pipe

Before you can install heat tape on your Pex pipe, it’s essential to properly prepare the pipe surface. This will ensure effective heat transfer and overall efficiency of the heat tape. In this section, we will guide you through the step-by-step process of cleaning the pipe surface and measuring the length for the heat tape.

Cleaning The Pipe Surface

Cleaning the pipe surface is crucial to remove any dirt, dust, or moisture that may hinder the proper adhesion of the heat tape. Follow these simple steps to clean the pipe surface effectively:

- Start by wiping the entire length of the Pex pipe with a clean, lint-free cloth. This will help remove any loose particles or debris.

- Next, dampen another cloth with isopropyl alcohol or a mild cleaning solution. Gently rub the cloth along the surface of the pipe, ensuring to cover all areas.

- Allow the pipe to dry completely before proceeding with the installation. This step is crucial to ensure proper adhesion of the heat tape.

Measuring The Length For Heat Tape

Accurately measuring the length for the heat tape is essential to ensure proper coverage and functionality. Here’s how you can measure the length:

- Begin by determining the total length of the Pex pipe that requires heat tape installation. Measure the entire length of the pipe, including any bends or twists.

- Add a few inches to the total length to account for overlapping of the heat tape at the ends. This extra length will ensure uniform heating throughout the pipe.

- Once you have the final length, cut the heat tape accordingly using a sharp pair of scissors or a utility knife. Be cautious while cutting to avoid damaging the tape.

By following these steps to clean the pipe surface and measure the length for the heat tape, you are now ready to move on to the next stage of the installation process. In the upcoming section, we will guide you through the steps of securing the heat tape and connecting it to the power source. Stay tuned!

Applying The Heat Tape

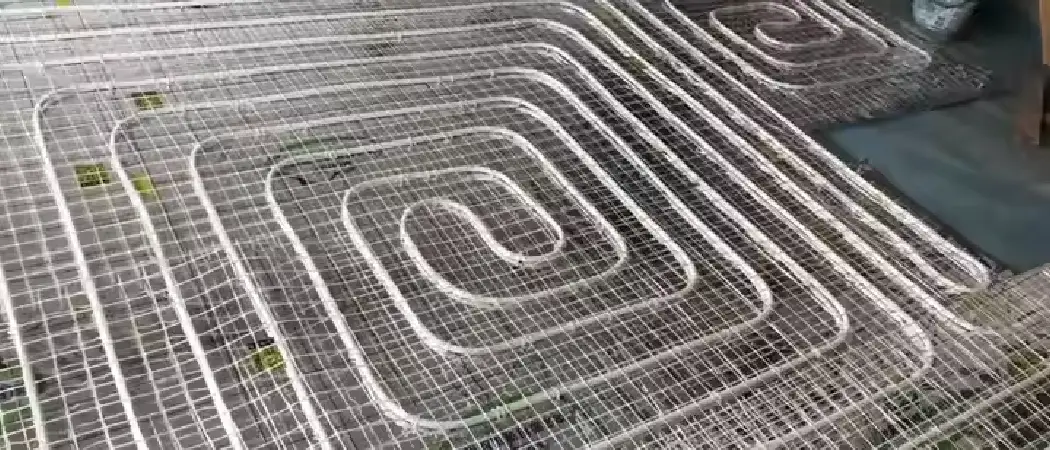

Applying heat tape to Pex pipe is an essential step to prevent freezing and bursting during cold weather. It provides an extra layer of insulation and ensures the pipe remains at a safe temperature. In this section, we will guide you through the process of applying heat tape on Pex pipe, highlighting the importance of ensuring proper insulation and the correct way to wrap the tape around the pipe.

Ensuring Proper Insulation

Before applying the heat tape, it is crucial to make sure that the Pex pipe is properly insulated. Insulation helps to retain the heat generated by the tape and prevents it from escaping into the surrounding environment.

Here are a few steps you can follow to ensure proper insulation:

- Start by measuring the length of the Pex pipe that needs to be insulated. This will help you determine the amount of insulation material required.

- Choose an insulation material that is suitable for Pex pipe. Foam insulation sleeves or tubes are commonly used for this purpose.

- Cut the insulation material to the appropriate length and slit it open. Then, wrap it around the Pex pipe, making sure there are no gaps or areas left exposed.

- Secure the insulation in place by using insulation tape or zip ties. This will help to keep it securely attached to the pipe.

- Inspect the insulation to ensure it is properly installed and there are no visible gaps or areas where the pipe is exposed. Adequate insulation is essential for the heat tape to work effectively.

Wrapping The Heat Tape Around The Pex Pipe

Once the Pex pipe is properly insulated, you can proceed with applying the heat tape. The heat tape should be wrapped around the pipe, ensuring that it is evenly distributed and in constant contact with the surface.

Here are the steps to follow for wrapping the heat tape:

- Start by unplugging the heat tape and making sure it is not connected to a power source.

- Hold the heat tape against the Pex pipe and begin wrapping it in a spiral motion along the length of the pipe. Ensure that each wrap overlaps the previous one slightly to avoid any gaps.

- Avoid stretching the heat tape too tightly while wrapping it around the pipe, as this may cause it to become less effective in transferring heat.

- Continue wrapping the heat tape until you reach the end of the Pex pipe or the recommended length specified by the manufacturer.

- Secure the end of the heat tape in place using electrical tape or zip ties. This will prevent it from unraveling and ensure a secure attachment to the pipe.

- Finally, connect the heat tape to a power source and adjust the thermostat if necessary. Make sure to follow the manufacturer’s instructions for proper usage and temperature settings.

By following these steps and ensuring proper insulation, you can confidently apply heat tape on Pex pipe to safeguard against freezing and potential damage. Taking the necessary precautions will help you maintain a well-functioning plumbing system and avoid costly repairs in the future.

Securing The Heat Tape

In order to ensure that your heat tape is properly secured to the Pex pipe, it is important to use proper fastening techniques and verify the tape’s placement. Here are some tips to help you in this process:

Using Proper Fastening Techniques

When securing the heat tape to the Pex pipe, it is essential to use the right fastening techniques to ensure that the tape stays in place. Here are some steps to follow:

- Start by cleaning the surface of the Pex pipe. Remove any dirt, debris, or moisture that may prevent the tape from adhering properly.

- Apply a high-quality adhesive tape around the pipe, covering the area where the heat tape will be installed. Make sure to firmly press the adhesive tape onto the pipe to create a strong bond.

- Wrap the heat tape tightly around the pipe, making sure to evenly distribute the tape along the entire length. Use zip ties or electrical tape to secure the heat tape at regular intervals, ensuring that it remains in place.

- For additional security, consider using heat-resistant aluminum foil tape to cover the entire length of the heat tape. This will provide extra protection against damage and help to keep the heat tape securely in place.

Verifying The Tape’s Placement

Once the heat tape is secured to the Pex pipe, it is important to verify its placement to ensure proper functionality and heat distribution. Follow these steps to ensure the tape’s correct positioning:

- Inspect the entire length of the heat tape to ensure that it is evenly wrapped around the pipe with no gaps or loose sections.

- Use a thermometer to measure the temperature along the length of the heat tape. Verify that the tape is providing consistent heat throughout its entire length.

- If you notice any areas where the heat tape is not providing sufficient heat or if there are any gaps or loose sections, adjust and secure the tape accordingly.

By using proper fastening techniques and verifying the tape’s placement, you can ensure that your heat tape is securely installed on the Pex pipe, providing efficient and effective heat distribution.

Connecting The Power Source

When installing heat tape on PEX pipes, connecting the power source is a critical step to ensure efficient heat distribution and protection against freezing. Properlyconnecting the power source to the heat tape will help maintain a safe and consistent temperature within the pipes, preventing potential damage due to cold weather conditions.

Checking The Electrical Outlet

Before plugging in the heat tape, it’s essential to ensure that the electrical outlet is in good working condition. Look for any signs of damage or wear on the outlet or the surrounding area. If there are any concerns about the outlet’s safety, it’s advisable to consult with a qualified electrician to address any issues. Ensure that the outlet is compatible with the heat tape’s power requirements to prevent any potential electrical hazards.

Safely Plugging In The Heat Tape

When plugging in the heat tape, carefully handle the power cord and ensure it is not frayed or damaged. Safely insert the plug into the electrical outlet, making sure it fits snugly and securely. Avoid overloading the electrical circuit by using the heat tape as the only device plugged into the outlet. It’s important to follow the manufacturer’s instructions and recommendations for the specific heat tape model to avoid any safety hazards or potential damage to the system.

Testing The Heat Tape

During the heat tape installation process, it is crucial to test the system to ensure it is functioning properly. This step is essential for preventing potential damage to the PEX pipe due to freezing temperatures. Testing the heat tape involves monitoring the heat distribution and verifying its performance using a thermal gun.

Monitoring For Proper Heat Distribution

Proper heat distribution is vital to prevent freezing in the PEX pipe. To ensure this, regularly monitor the temperature along the pipe’s length. Check for any cold spots which may indicate inadequate heat distribution. Additionally, verify that the heat tape is in direct contact with the pipe without any gaps or folds, as this can lead to uneven heating. Make sure that the heat tape is secure and properly insulated to maintain consistent warmth throughout the entire length of the PEX pipe.

Verifying The Performance With A Thermal Gun

Using a thermal gun allows for accurate measurement of the temperature of the PEX pipe. Point the thermal gun at various sections along the pipe to ensure that the heat tape is providing uniform warmth. Look for any temperature fluctuations or irregularities that may indicate potential issues with the heat tape. This method also helps in identifying any hot spots, which can indicate an excessive heat output that may lead to damage if not addressed.

Ensuring Long-term Effectiveness

Regular Maintenance Checks

Troubleshooting And Potential Solutions

Ensuring Long-Term Effectiveness:

Installing heat tape on Pex pipework is an essential step in ensuring long-term effectiveness. Proper installation and regular maintenance are crucial to prevent any issues in the future.

Regular Maintenance Checks

Regularly inspect the heat tape for any visible damage or wear, and ensure that it is still properly secured to the Pex pipe.

Consider using a thermostat to monitor the heat tape’s temperature, ensuring it remains at the optimal level.

Inspect for potential leaks or irregularities in the pipework, as these can affect the heat tape’s performance.

Troubleshooting And Potential Solutions

If you notice any issues with the heat tape, such as uneven heating or failure to turn on, check the power source and connections first.

If the heat tape still does not function properly, consider replacing it with a new one to ensure efficient operation.

Consult a professional if you encounter persistent issues with the heat tape or Pex pipe system.

Providing regular maintenance checks and being aware of troubleshooting options will help maintain the effectiveness of heat tape on Pex pipe over time.