To cover screw holes in metal, use a putty or filler that matches the metal’s color. This will seamlessly hide the holes and provide a smooth surface.

Screw holes in metal can be unsightly and may even affect the metal’s structural integrity. Fortunately, there’s an easy way to cover them up. By following these simple steps, you can make your metal surface look as good as new.

First, gather the necessary supplies – putty, sandpaper, a putty knife, and matching paint. Then, apply the putty or filler to the screw hole using the putty knife, making sure to fill it completely. Once dry, sand the surface smooth and paint over it with the matching color. With just a few steps, your metal surface will be restored to its original condition.

Traditional Methods Of Covering Screw Holes

In traditional metalworking, the common techniques for covering screw holes were welding or using metal patches. However, in modern times, these methods may not be the most effective or efficient ways to cover screw holes. Here are some reasons why:

- Welding requires specialized equipment and expertise. It can also damage the metal around the screw hole, resulting in weakened or distorted areas.

- Metal patches require precise cutting and shaping to fit properly, which can be time-consuming and challenging.

There are also several disadvantages to these traditional methods:

- They can be costly, especially when hiring a professional welder or metalworker.

- They may only be suitable for certain types of metal, making them unsuitable for some projects.

- The results may not always be aesthetically pleasing, especially if the metal around the screw hole is discolored or distorted.

Overall, while traditional methods of covering screw holes were effective in their time, there are now more efficient and cost-effective methods available for modern metalworkers and diy enthusiasts.

Innovative Methods Of Covering Screw Holes

Modern And Improved Methods For Covering Screw Holes In Metal

Screw holes that are left uncovered can lead to corrosion, rust and damage to the surface of the metal. There are numerous methods to cover screw holes, and some are more modern and innovative than others. In this section, we will explore these improved methods that will give a new lease of life to the damaged metal surface.

Self-Adhesive Metal Covers

Self-adhesive metal covers are a simple and convenient way to cover screw holes in metal. These metal covers are available in a range of sizes and materials such as stainless steel, aluminum, and brass, that match most metal surfaces. The covers are self-adhesive, making them easy to install and remove.

A perfect solution for small areas and where aesthetics are essential.

- Quick and easy to use with no additional tools required.

- Can be cut to size or fit with different shapes.

- Durable and rust-resistant, providing a long-lasting solution.

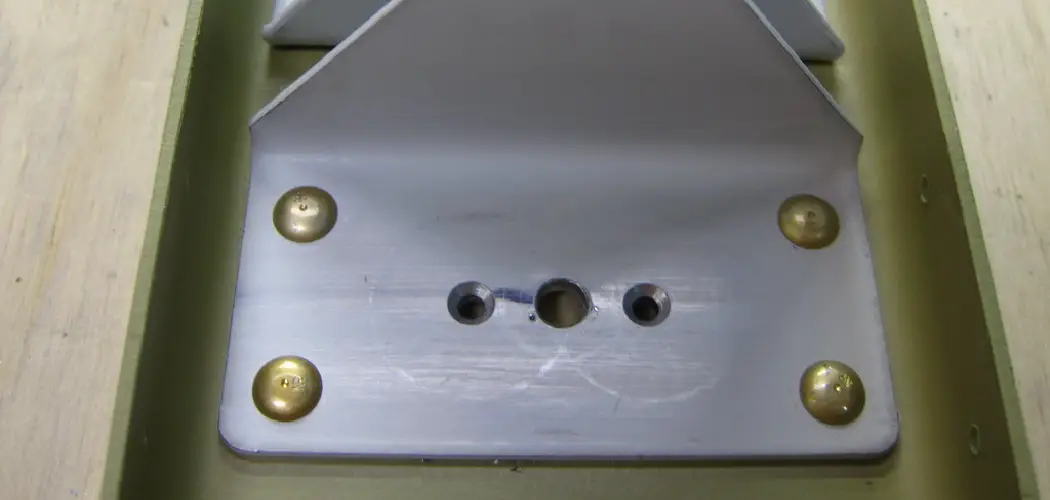

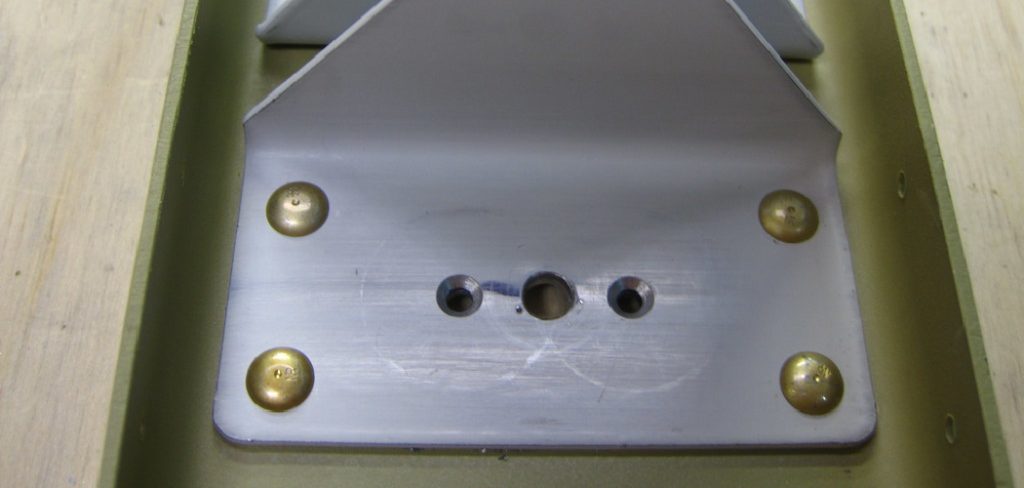

Metal Patch Plates

Metal patch plates are another excellent solution for covering screw holes in metal. These patches come in a variety of materials and sizes that can be matched to the damaged surface. You can use glue or an adhesive to attach the plates to the surface of the metal.

- The patch plates protect the structure against the spread of corrosion.

- These plates provide affordable flexibility and protection, which are quite essential in outdoor settings.

- They come in different sizes to cover a wide range of screw holes.

Sealants

Sealants are versatile tools that are often used to repair holes in metal. They can be made from a range of materials such as butyl, silicone, and polyurethane. Applying sealant is a cost-effective and professional way to cover screw holes from exposure to moisture, dirt, and other elements.

- Sealants can be applied to metal surfaces in small or large areas.

- They offer years of protection against rust, moisture leakage, and other exposures.

- Sealants are easy to apply with a simple sealant gun and easy to remove with a razor blade.

Epoxy Putty

Epoxy putty is another fantastic method of covering screw holes in metal. Epoxy putty is a two-part putty that hardens after mixing. It is a versatile method used to repair holes, cracks or scratches in metal.

- Epoxy putty is one of the most reliable methods for covering screw holes.

- Epoxy putty is easy and flexible to use which dries hard after curing.

- It can be used on dry and wet surfaces, making it the perfect solution for the most complex holes and surface shapes.

Metal Shavings

The most natural and cost-effective method for covering screw holes in metal is using scrap metal shavings. These metal shavings can be collected from metal fabrication shops or other sources of scrap metal. Once collected, the shavings can be used as ‘filler’ to cover screw holes and other surface imperfections.

- A cheap and easy solution.

- Suitable for temporary repairs, or small areas where the aesthetics are not essential.

- The metal chips are environmentally friendly and do not require chemicals or additional fillers.

When it comes to covering screw holes in metal, there are several modern and innovative methods available. From self-adhesive metal covers and metal patch plates to epoxy putty and scrap metal shavings, each method has its own unique advantages and benefits.

Remember to choose the best one depending on your needs.

Investment Tools For Covering Screw Holes

Covering screw holes in metal might seem like a minor issue. But, if left unaddressed, corrosion, rust, and discoloration can occur, compromising the integrity and aesthetics of metal surfaces. While many affordable and straightforward methods exist for covering screw holes, specialized investment tools can provide accurate solutions, resulting in a seamless finish.

In this section, we dive into the specialized and expensive investment tools that have been developed explicitly for covering screw holes in metal.

Pneumatic Punch

A pneumatic punch is a specialized tool used for punching a hole in metal to create a perfect match with existing screw holes. The tool works by turning compressed air into a repetitive punching motion that quickly punches out a small disc of metal.

Pros:

- Creates a seamless finish

- Best suited for punching a high number of holes

- Quick and accurate

Cons:

- High initial investment cost

- Requires a compressor for operation

- Takes time to set up and learn

Vibratory Tumbler

A vibratory tumbler is a machine used to polish metal surfaces, and its specialized use is to smooth out the rough edges created after covering screw holes. The machine holds metal parts and small objects while vibrating and tumbling them in an abrasive medium, resulting in a smooth finish.

Pros:

- Suitable for large batches of metal parts

- Can be used for polishing and deburring

- Offers a consistent finish

Cons:

- Expensive compared to other methods

- Noisy during operation

- May cause welds to fail if not done accurately

Sheet-Cutting Punch

A sheet-cutting punch is a specialized tool used to cut out a precisely shaped circle of metal that matches the screw hole. The tool’s design minimizes any burrs created during the punching process, leaving a clean edge for use as a cover plate.

Pros:

- Precise and accurate

- Self-centering design for consistent results

- Suitable for low-volume jobs

Cons:

- High initial cost

- Limited to specific sizes and shapes

- Requires physical energy to operate

Investment tools for covering screw holes in metal can be expensive but offer professional and accurate results. The decision to invest in these tools depends heavily on the scale of the project, volumes required, and the desired outcome. That said, if the project requires a high level of accuracy and a professional finish, investment tools such as pneumatic punches, vibratory tumblers, and sheet-cutting punches offer the perfect solution.

Covering Screw Holes For Different Types Of Metal

Covering screw holes in metal surfaces can be a hassle, especially if you’re unfamiliar with the proper techniques or materials needed for each type of metal. Whether you’re dealing with stainless steel, aluminum, or brass, it’s important to know which materials or tools work best to cover holes effectively.

Here, we’ll explore each type of metal and the best approaches for covering screw holes.

Stainless Steel

When it comes to covering screw holes on stainless steel surfaces, you’ll need to use some specific materials to achieve the desired results:

- Stainless steel putty: This is specially formulated for use on stainless steel surfaces and provides excellent bonding and sealing properties.

- Epoxy putty: This is also a good choice for stainless steel surfaces and can be used as an alternative to stainless steel putty.

Aluminum

Covering screw holes on aluminum surfaces requires a different approach. Using the wrong materials can simply worsen the problem, leaving unsightly marks or causing even more damage. Here are some of the best materials to use on aluminum surfaces:

- Aluminum putty: This is specially designed for use on aluminum surfaces and can provide good bonding and filling properties.

- Silicone sealant: This can be used as an alternative to aluminum putty, and provides excellent waterproofing and heat-resistant properties.

Brass

Lastly, covering screw holes in brass surfaces may require different tools and materials than those used for stainless steel or aluminum. This is because brass can easily oxidize and tarnish if exposed to certain substances or environments. Here are some of the best materials to use on brass surfaces:

- Brass putty: This is specially formulated for use on brass surfaces and can provide excellent bonding and sealing properties.

- Lacquer: This can be used as an alternative to brass putty and is excellent for preventing oxidation and tarnishing on brass surfaces.

When it comes to covering screw holes in metal surfaces, it’s important to use the right tools and materials for each specific type of metal. Choosing the wrong materials can simply worsen the problem, leaving unsightly marks or causing even more damage.

So, be sure to follow the techniques and materials outlined above to achieve the best results for each type of metal.

Frequently Asked Questions Of How To Cover Screw Holes In Metal

What Are Screw Holes In Metal And Why Should They Be Covered?

Screw holes in metal are empty spaces left by screws. Covering them improves the metal’s appearance and weather resistance.

What Materials Can Be Used To Cover Screw Holes In Metal?

There are several materials that can be used to cover screw holes, including silicone, epoxy, and metal plugs.

How Can I Match The Color Of The Screw Hole Cover To The Metal?

To match the color of the screw hole cover to the metal, paint can be used. It is important to choose a paint that is designed for metal surfaces.

What Tools Are Needed To Cover Screw Holes In Metal?

The tools needed to cover screw holes in metal include a drill and drill bits, sandpaper, a putty knife, and the material being used to cover the hole.

How Can Screw Holes In Metal Be Prevented In The First Place?

To prevent screw holes in metal, self-tapping screws can be used instead of traditional screws. This type of screw creates its own hole, reducing the risk of damage to the metal.

Conclusion

Covering screw holes in metal is an easy and inexpensive way to give your project a finished look. With the right tools and materials, you can effectively cover any unsightly screw holes in your metal surfaces. By following the steps provided above, you can achieve professional and clean-looking results every time.

When it comes to metalworking, attention to detail is crucial, and filling in screw holes can make a big difference in the overall appearance of your project. Whether you’re a diy enthusiast or a professional metalworker, this technique should not be overlooked.

So why not give it a try? With a little practice, you can become a pro at covering screw holes in metal and take your metalworking creations to the next level.